1. What Are PEEK Machine Screws?

Definition of PEEK screws

Overview of PEEK plastic as an engineering material

Why PEEK material is chosen over metals and other plastics

2. Key Properties of PEEK Screws

Excellent strength per weight ratio

High corrosion resistance

Stable in High Heat and temperature

Non-conductive and insulating properties

Biocompatibility for medical and cleanroom use

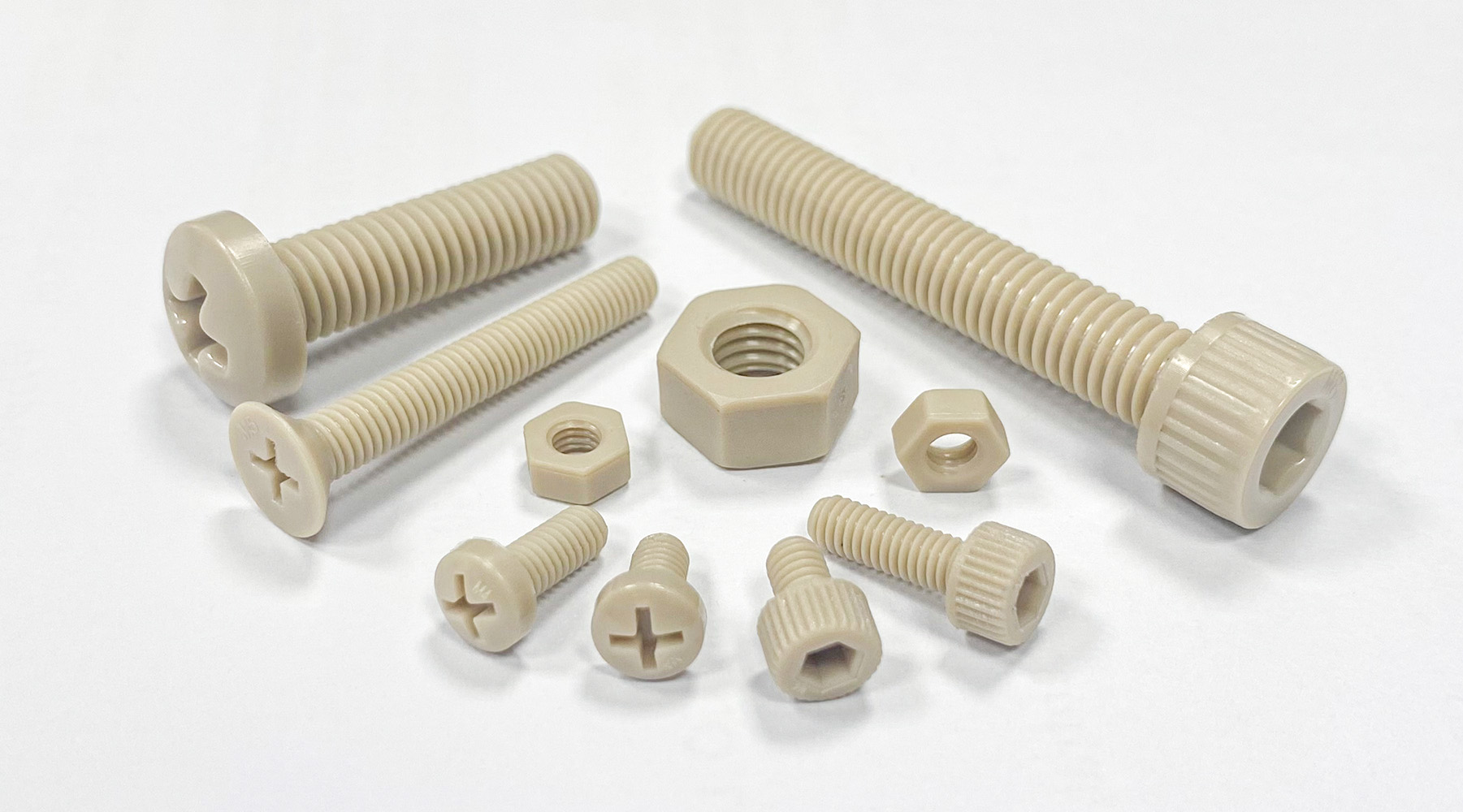

3. Common Types of PEEK Machine Screws

Pan head, flat head, socket head, countersunk, Torx, Phillips

Thread sizes available (M2–M16)

Custom options for OEMs and industrial buyers

4. Advantages of Buying PEEK Screws Wholesale

Lower cost per unit

Consistent quality and supply reliability

Customization opportunities with bulk orders

Supplier partnerships for long-term projects

5. Industry Applications of PEEK Machine Screws

Aerospace: reduce the weight of body, high-heat environments

Medical equipment: dental tools, Inspection equipment

Machinery equipment: pumps, valves, chemical equipment

6. Comparing PEEK Screws to Metal Fasteners

PEEK vs stainless steel screws

PEEK vs titanium

Weight savings and corrosion resistance benefits

Long-term performance and lifecycle cost analysis

7. Standards & Compliance for PEEK Fasteners

ISO, DIN, ASTM standards

FDA and medical certifications

Aerospace and defense compliance

8. Custom Manufacturing Options for Wholesale Buyers

CNC machining for special dimensions

Custom head types and thread patterns

Private label and OEM services

Color-matched or special-grade PEEK material

9. Conclusion: Why PEEK Screws Are the Future of High-Performance Fasteners

Summary of wholesale benefits

Industries driving growth in demand

Call to action for businesses to consider PEEK in their next bulk order